A concrete pipe with a thin steel core: combines

the strength of prestressed concrete

with the tightness of steel, with an internal and external concrete lining

protecting the pipe against corrosion.

PCPP is a historically reliable product with a new improved faster manufacturing process that makes it

possible to compete with GRP and steel pipes.

Witech Environment, incorporated in the UAE, supplies high-quality European pressure water pipes and establishes production facilities in strategic locations through joint ventures, direct foreign investment, or by supporting local partners.

CONTENT

Copyright - Witech 2024 - contact@witech-environment.com

PRESTRESSED CONCRETE PRESSURE PIPES (PCPP)

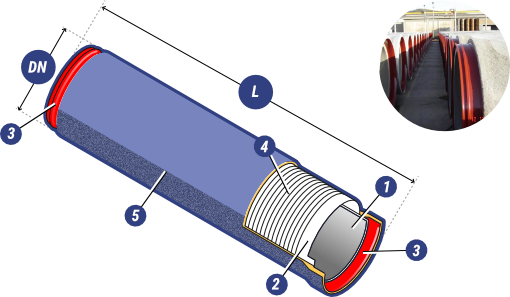

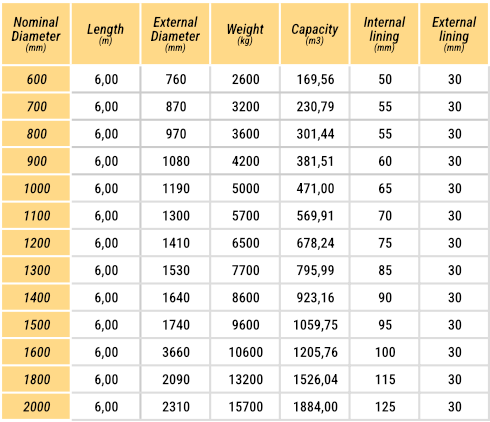

Standard thickness

1 Concrete core: 50 to 125mm, 2 Steel cylinder: 1,5mm,

3 Steel rings: 8mm, 4 Prestressing wire: 5mm,

5 Mortar coating: 30mm, DN 600 to 2000mm,

L6m

APPLICATIONS

PCP pipes are perfectly suited to transport

WATER or WASTEWATER, with temperatures between

-35°C and 50°C, in

pressured pipelines up to 30 bars

(usual pressure 5 to 20 bars) or by

gravity flow.

This technology has been used successfully and is recommended for the following applications:

This technology has been used successfully and is recommended for the following applications:

• Water Transmission Lines

• Water Distribution Mains

• Dam Principal Spillways

• Chilled Water Lines

• Wastewater Gravity Sewers

• Wastewater Force Mains

• Wastewater Treatment Plants – Process Lines

• Water Treatment Plants – Process Lines

• Industrial Process Lines

• Power Plant Cooling Lines

• Power Plant Make-up Water Lines

• Subaqueous Intake Lines

• Subaqueous Outfall Lines

• Pile Supported Lines

• Carrier Pipe in Tunnel Casings

• Water Distribution Mains

• Dam Principal Spillways

• Chilled Water Lines

• Wastewater Gravity Sewers

• Wastewater Force Mains

• Wastewater Treatment Plants – Process Lines

• Water Treatment Plants – Process Lines

• Industrial Process Lines

• Power Plant Cooling Lines

• Power Plant Make-up Water Lines

• Subaqueous Intake Lines

• Subaqueous Outfall Lines

• Pile Supported Lines

• Carrier Pipe in Tunnel Casings

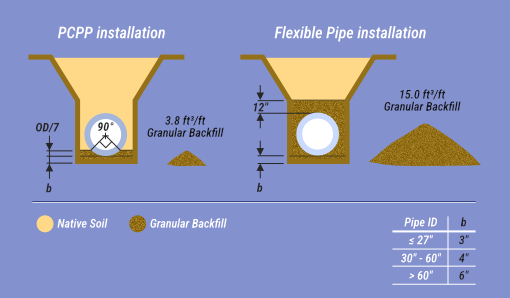

INSTALLATION

ECONOMICAL EARTHWORKS

Compared to flexible pipes (GRP, steel, or ductile iron pipes), PCPP rigid

structure :

structure :

• Requires less out-of-site backfill, generating significant savings during installation

• Makes it less sensitive to ground movement

• Offers better mechanical resistance to external loads: standard pipe depth of 3 to 6m (above the top of the pipe) without any additional pipe protection or design modification

• Makes it less sensitive to ground movement

• Offers better mechanical resistance to external loads: standard pipe depth of 3 to 6m (above the top of the pipe) without any additional pipe protection or design modification

EXAMPLE : 36" CONCRETE AND FLEXIBLE PIPE INSTALLED IN A TRENCH

SIMPLE ASSEMBLY AND HANDLING

Pipe laying and assembly require standard machinery and handling equipment.

• Standard spigot/bell push-on joints with elastomeric gasket (simple or double), can be made

air-testable

• Restrained welded joints for specific design needs

• Restrained welded joints for specific design needs

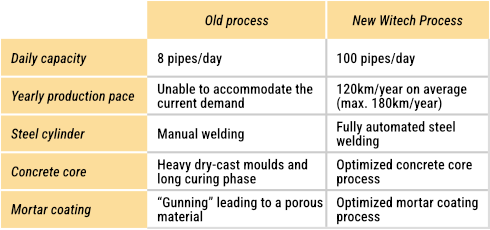

WITECH FACTORY DESIGN

We combined the latest machines on the production line to improve the manufacturing capacity and final

product quality.

KEY NUMBERS FOR ONE WITECH FACTORY

• Plot size 50 000 sqm

• Preparation time: 6 months to 1 year

• Factory construction time: 1 year

• Factory area: 15 700sqm

• 120km/year for the average pipe (DN1200, 12bar, 6lm)

• Number of employees: 300

• 2x8h shifts/day

• Operating 300days/year

• Preparation time: 6 months to 1 year

• Factory construction time: 1 year

• Factory area: 15 700sqm

• 120km/year for the average pipe (DN1200, 12bar, 6lm)

• Number of employees: 300

• 2x8h shifts/day

• Operating 300days/year

PCPP DETAILED CHARACTERISTICS

• First pipelines installed in the 1940s in the USA

• A proven and reliable technology widely used in the USA, Canada, Europe, and North Africa mainly for waterpressured pipelines

• Lifespan of 80 to 100 years

• Naturally protected against corrosion by the external and internal concrete lining

• Price competitive: 40 to 60% less expensive than other pipes technologies

• Optimized installation cost due to the pipe rigidity and mechanical resistance

• Earthquake resistant

• A proven and reliable technology widely used in the USA, Canada, Europe, and North Africa mainly for waterpressured pipelines

• Lifespan of 80 to 100 years

• Naturally protected against corrosion by the external and internal concrete lining

• Price competitive: 40 to 60% less expensive than other pipes technologies

• Optimized installation cost due to the pipe rigidity and mechanical resistance

• Earthquake resistant